In today’s fast-paced industrial environment, efficiency is key. One tool that significantly enhances productivity in glass processing is the Glass Cutting Machine. Whether you are in construction, interior design, or glass manufacturing, understanding how to optimize your workflow with a glass cutting machine can save time, reduce costs, and improve the quality of your work. This article explores practical ways to increase productivity while using a Glass Cutting Machine.

Understanding the Glass Cutting Machine

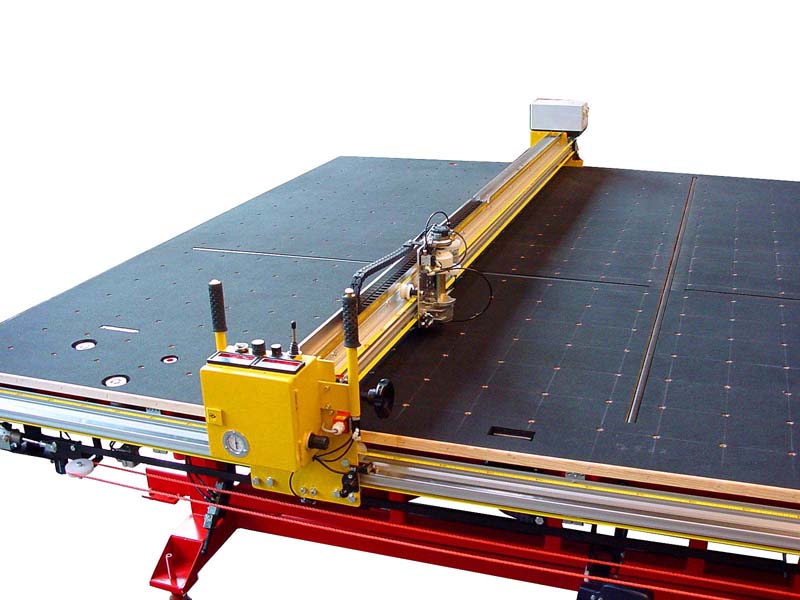

A Glass Cutting Machine is designed to score and cut glass with precision and speed. Unlike manual cutting, which requires skill and can be inconsistent, a glass cutting machine ensures uniformity, reduces breakage, and allows for complex shapes and sizes. There are various types of glass cutting machines available in the market, including manual, semi-automatic, and fully automatic models. Each type offers unique advantages depending on your production scale and requirements.

Choosing the Right Glass Cutting Machine

The first step toward increasing productivity is selecting the appropriate Glass Cutting Machine for your operation. Consider the following factors:

- Type of Glass: Different machines handle different thicknesses and types of glass, including tempered, laminated, or float glass. Choosing a machine compatible with your material is essential.

- Production Volume: For high-volume production, automatic glass cutting machines are ideal as they can cut multiple sheets with minimal human intervention.

- Precision Requirements: If your work demands high precision, opt for machines with computer numerical control (CNC) capabilities.

- Maintenance and Durability: A durable machine with low maintenance needs ensures minimal downtime, which is crucial for maintaining productivity.

Preparing Your Workspace

A well-organized workspace is essential to maximize the efficiency of a Glass Cutting Machine. Ensure that your work area is clean, well-lit, and free of obstructions. Proper layout of glass sheets, tools, and safety equipment allows operators to work faster and reduces the risk of accidents. Additionally, maintaining an ergonomic setup for the machine operator can prevent fatigue and improve focus, leading to higher productivity.

Training and Skill Development

Even though a Glass Cutting Machine simplifies the cutting process, proper training is vital. Operators should understand the machine’s functions, safety protocols, and troubleshooting techniques. Investing in training programs not only increases the speed and efficiency of operations but also reduces errors and breakages. Skilled operators can take full advantage of advanced features, such as automated cutting patterns and batch processing, further enhancing productivity.

Regular Maintenance and Inspection

Productivity is heavily dependent on the reliability of your Glass Cutting Machine. Regular maintenance ensures that the machine operates smoothly and prevents unexpected breakdowns. Routine tasks include cleaning the cutting surface, lubricating moving parts, checking alignment, and replacing worn-out blades. A well-maintained machine cuts faster, more accurately, and with fewer defects, ultimately saving time and materials.

Optimizing the Cutting Process

Optimizing your cutting process is crucial for maximizing productivity. Here are strategies to consider:

- Batch Cutting: Group glass sheets of similar sizes and cut them in batches to minimize setup time.

- Automated Programs: Use CNC or automated settings to cut complex shapes with minimal manual intervention.

- Blade Selection: Choose the right cutting blade for the type and thickness of glass. Sharp blades reduce resistance, prevent chipping, and speed up the cutting process.

- Minimizing Movement: Arrange glass sheets and cutting tools to minimize unnecessary movement, reducing the operator’s fatigue and speeding up production.

Safety Considerations

Safety should never be overlooked when using a Glass Cutting Machine. Injuries can halt production and reduce efficiency. Ensure operators wear protective gear, including gloves, safety glasses, and protective clothing. Install safety barriers, emergency stops, and proper ventilation to handle glass dust and shards. A safe environment allows operators to work confidently and maintain a steady pace, which directly impacts productivity.

Leveraging Technology

Modern Glass Cutting Machines often come equipped with advanced technology to enhance productivity. Features like laser guides, automatic feed systems, and integrated software can streamline operations. For instance, laser guides help operators make precise cuts without measuring manually, while software can optimize cutting patterns to minimize waste. By leveraging these technologies, businesses can achieve higher throughput with consistent quality.

Monitoring Performance

To continually improve productivity, monitor the performance of your Glass Cutting Machine. Track metrics such as the number of sheets processed per hour, the rate of breakage, and the time spent on setup. By analyzing this data, you can identify bottlenecks and implement changes to enhance efficiency. Continuous improvement ensures that your investment in a glass cutting machine delivers maximum returns.

Reducing Material Waste

Efficient use of glass reduces costs and increases productivity. Plan cuts carefully to minimize scrap and reuse offcuts whenever possible. Advanced machines allow you to input dimensions and receive optimized cutting layouts, reducing waste significantly. Less waste means less time spent handling excess material and lower expenses, contributing to overall productivity.

Integrating with Other Processes

A Glass Cutting Machine should not operate in isolation. Integrate it with other processes such as polishing, edging, or assembly to create a streamlined workflow. Coordinating cutting schedules with other production steps reduces downtime between operations and ensures a smooth, continuous process.

Conclusion

Increasing productivity with a Glass Cutting Machine involves a combination of proper machine selection, operator training, optimized cutting processes, regular maintenance, and technological integration. By focusing on efficiency and precision, businesses can reduce waste, minimize downtime, and produce high-quality glass products consistently. Whether you are a small workshop or a large manufacturing facility, leveraging the full potential of a Glass Cutting Machine can significantly enhance your productivity and profitability.

Using these strategies ensures that every cut counts, every sheet is utilized effectively, and every operator can work at peak performance, making the Glass Cutting Machine an indispensable asset for modern glass processing operations.