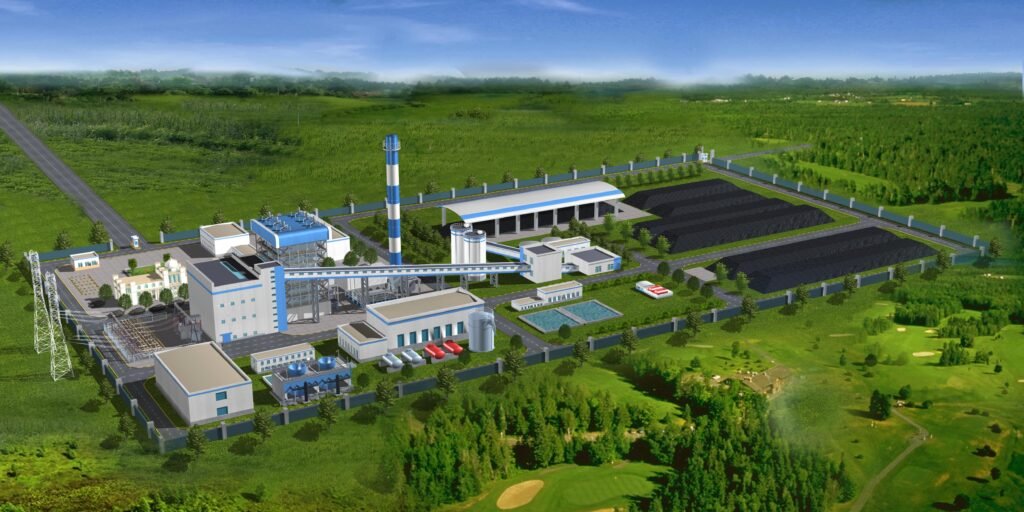

Thermal power plants operate under demanding conditions where high temperatures, pressure variations, and continuous mechanical stress are part of daily operations. In such an environment, maintenance efficiency directly impacts plant reliability, safety, and profitability. One of the most effective strategies to enhance maintenance performance is the use of customized spare parts for thermal power plants. Rather than relying on generic, off-the-shelf components, plant operators are increasingly turning to tailored solutions that align precisely with their operational requirements. This approach not only minimizes downtime but also extends equipment life and improves overall plant efficiency.

RUNH POWER has positioned itself as a trusted name in providing engineered solutions that support thermal power plant maintenance through precision, quality, and customization.

Understanding the Maintenance Challenges in Thermal Power Plants

Thermal power plants consist of complex systems such as boilers, turbines, generators, mills, conveyors, and auxiliary equipment. Each component is exposed to wear and tear due to continuous operation and harsh environmental conditions. Common maintenance challenges include unexpected equipment failure, frequent shutdowns, difficulty sourcing compatible spare parts, and rising operational costs.

Standard spare parts often fail to address plant-specific issues such as design variations, aging equipment, or modified operating conditions. This mismatch can lead to repeated failures and inefficient repairs. Customized spare parts for thermal power plants directly address these challenges by being designed to match exact specifications and operational demands.

What Are Customized Spare Parts?

Customized spare parts are components that are specifically designed, engineered, and manufactured to meet the unique requirements of a particular thermal power plant or piece of equipment. Unlike standard parts, these spares consider factors such as load conditions, material compatibility, operating temperature, corrosion resistance, and equipment modifications.

RUNH POWER focuses on delivering customized solutions that integrate seamlessly with existing systems, ensuring improved performance and long-term reliability. Customization may involve material upgrades, dimensional adjustments, enhanced wear resistance, or design optimization to improve efficiency.

Benefits of Customized Spare Parts for Thermal Power Plants

Improved Equipment Reliability

One of the most significant advantages of customized spare parts for thermal power plants is enhanced reliability. When parts are designed specifically for a plant’s operating conditions, the risk of premature failure is greatly reduced. This results in fewer breakdowns and more predictable maintenance schedules.

Customized components from RUNH POWER are engineered to withstand specific thermal and mechanical stresses, ensuring consistent performance even under extreme conditions.

Reduced Downtime and Maintenance Costs

Unplanned downtime is one of the costliest issues in thermal power generation. Generic spare parts may require frequent replacement or adjustments, leading to extended shutdowns. Customized spare parts fit correctly the first time, reducing installation time and minimizing operational interruptions.

Although customized components may have a higher initial cost, they significantly lower long-term maintenance expenses by reducing repair frequency and improving equipment lifespan.

Extended Equipment Life

Thermal power plant equipment represents a major capital investment. Customized spare parts help protect this investment by reducing wear on critical components. By selecting appropriate materials and optimized designs, customized spares minimize friction, corrosion, and thermal fatigue.

RUNH POWER emphasizes durability and performance in its customized solutions, helping plant operators extend the service life of key equipment and delay costly replacements.

Key Applications of Customized Spare Parts in Thermal Power Plants

Boiler and Combustion Systems

Boilers operate under extreme heat and pressure, making them highly susceptible to wear. Customized spare parts such as burner components, liners, and seals are essential for maintaining combustion efficiency and safety. Tailored designs ensure optimal fuel-air mixing and reduce the risk of leaks or uneven heating.

Turbine and Generator Components

Turbines and generators demand precision and balance to operate efficiently. Customized spare parts for thermal power plants, including bearings, shafts, and sealing components, ensure smooth operation and reduce vibration-related damage. Precision-engineered parts from RUNH POWER support higher efficiency and stable power output.

Material Handling and Auxiliary Systems

Coal handling systems, ash conveyors, and auxiliary equipment also benefit from customization. Customized wear-resistant liners, rollers, and conveyor components improve material flow and reduce maintenance frequency. These improvements contribute to overall plant efficiency and safer operations.

Role of Engineering and Material Selection

Customization goes beyond dimensional accuracy. Engineering analysis and material selection play a critical role in ensuring spare part performance. Factors such as abrasion resistance, thermal expansion, corrosion protection, and mechanical strength must be carefully evaluated.

RUNH POWER integrates engineering expertise with advanced manufacturing techniques to deliver customized spare parts for thermal power plants that meet international quality standards. This approach ensures that each component performs reliably throughout its service life.

Inventory Optimization and Supply Chain Benefits

Maintaining a large inventory of generic spare parts can tie up capital and increase storage costs. Customized spare parts allow plants to streamline inventory by stocking only critical, application-specific components. This targeted approach improves inventory management and ensures faster response during maintenance activities.

By partnering with a reliable supplier like RUNH POWER, thermal power plants can benefit from consistent availability, technical support, and reduced procurement complexity.

Enhancing Safety and Compliance

Safety is a top priority in thermal power plant operations. Poorly fitting or incompatible spare parts can pose serious safety risks, including leaks, mechanical failures, and operational hazards. Customized spare parts are designed to meet specific safety and regulatory requirements, reducing the likelihood of accidents.

RUNH POWER prioritizes quality control and compliance, ensuring that customized components support safe and stable plant operations.

Supporting Sustainable and Efficient Power Generation

As the power generation industry moves toward greater efficiency and sustainability, maintenance strategies must evolve accordingly. Customized spare parts contribute to improved energy efficiency by reducing losses, enhancing combustion performance, and supporting optimal equipment operation.

By extending equipment life and reducing waste from frequent replacements, customized spare parts for thermal power plants also support environmental sustainability goals.

Why Choose RUNH POWER for Customized Spare Parts

RUNH POWER combines industry experience, engineering expertise, and a commitment to quality to deliver customized spare parts that meet the specific needs of thermal power plants. The company understands the operational challenges faced by power producers and focuses on providing reliable, long-term solutions rather than temporary fixes.

With a strong emphasis on customization, performance optimization, and customer support, RUNH POWER helps plant operators achieve higher availability, lower maintenance costs, and improved operational efficiency.

Conclusion

Customized spare parts have become a critical component of effective thermal power plant maintenance strategies. By addressing plant-specific challenges, enhancing reliability, and reducing downtime, customized spare parts for thermal power plants offer clear operational and financial benefits. As power plants continue to operate under demanding conditions, the importance of precision-engineered, application-specific components will only grow.