The manufacturing and logistics industries have witnessed a significant transformation over the past few decades, driven largely by advancements in automation and material handling technology. Among the key innovations shaping this evolution is the use of plastic chain belt in automated sorting systems. These belts offer a combination of durability, flexibility, and efficiency that makes them essential for modern production and distribution facilities. As industries continue to demand faster, more reliable, and cost-effective solutions, the future of automated sorting is increasingly intertwined with the capabilities of plastic chain belts.

Understanding Plastic Chain Belts

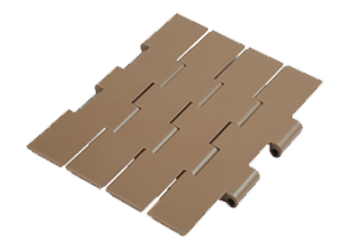

Plastic chain belts are specialized conveyor components made from high-performance polymers, engineered to replace traditional metal or rubber belts in certain applications. Unlike conventional conveyor belts, plastic chain belts consist of interlocking modular segments that form a continuous chain. This design allows them to handle heavy loads, resist wear and tear, and navigate complex conveyor layouts with ease. One of the most significant advantages of plastic chain belts is their modularity, which enables easy replacement of individual sections without the need to dismantle the entire conveyor system. This not only reduces maintenance downtime but also minimizes overall operational costs.

The versatility of plastic chain belts allows them to be customized for a wide range of applications. They can be designed with smooth surfaces for delicate products, textured surfaces for grip, or perforations for airflow and drainage. This adaptability makes them suitable for industries ranging from food processing and packaging to electronics and automotive manufacturing.

Advantages of Automated Sorting with Plastic Chain Belts

Automated sorting systems have become critical in modern warehouses and production lines, where efficiency and accuracy directly impact profitability. Plastic chain belts enhance these systems in several ways. First, their precision engineering ensures consistent movement of items along the conveyor path, which is essential for high-speed sorting operations. Unlike traditional belts that may slip or stretch over time, plastic chain belts maintain consistent pitch and alignment, enabling reliable detection and sorting of products.

Second, plastic chain belts are inherently resistant to many environmental factors. They can withstand exposure to water, chemicals, and extreme temperatures, making them suitable for challenging environments such as food processing plants, pharmaceutical facilities, and outdoor logistics hubs. This durability reduces the frequency of belt replacements and associated labor costs.

Another advantage lies in their ability to handle diverse product shapes and sizes. Traditional flat belts may struggle with irregularly shaped items, leading to misalignment or jams. Plastic chain belts, with their interlocking design, can accommodate variations in load geometry, ensuring smooth and uninterrupted flow through sorting machinery. This capability is particularly valuable in e-commerce fulfillment centers, where a wide variety of packages move through automated sorting systems daily.

Innovations Driving the Future

The future of automated sorting with plastic chain belts is being shaped by ongoing technological innovations. One key trend is the integration of smart sensors and IoT-enabled monitoring systems. By embedding sensors within the conveyor network, facilities can track belt performance in real-time, predict maintenance needs, and optimize sorting operations. For instance, if a section of a plastic chain belt shows signs of wear or misalignment, the system can alert operators before a failure occurs, minimizing downtime and preventing costly disruptions.

Robotics is also playing a pivotal role in advancing sorting systems. Plastic chain belts provide a stable and predictable surface for robotic arms to pick and place items with high accuracy. This synergy between conveyor technology and robotics enables faster throughput, reduced human labor, and improved workplace safety. As artificial intelligence continues to enhance machine learning algorithms, automated sorting systems will become more adaptive, capable of handling increasingly complex tasks with minimal human intervention.

Sustainability is another critical factor driving innovation in plastic chain belts. Modern manufacturing emphasizes eco-friendly materials and processes, and plastic chain belts are no exception. Many manufacturers now produce belts from recyclable or bio-based polymers, reducing the environmental footprint of automated sorting systems. Additionally, the modular design of these belts ensures that worn sections can be replaced individually, extending the lifespan of the system and minimizing waste.

Applications Across Industries

The adoption of plastic chain belts in automated sorting is widespread across multiple industries. In the food and beverage sector, these belts are ideal for handling packaged goods, bottles, cans, and delicate items such as fruits and vegetables. Their resistance to moisture, chemicals, and temperature fluctuations ensures hygiene standards are maintained while maintaining high sorting speeds.

In logistics and e-commerce, plastic chain belts are integral to conveyor networks that move packages through sorting centers. They enable precise alignment for barcode scanning, labeling, and routing, ensuring timely delivery to customers. The belts’ modularity also allows logistics operators to reconfigure conveyor layouts quickly in response to seasonal demand or changes in product mix.

The automotive industry benefits from plastic chain belts in assembly lines, where heavy parts and components must be transported reliably and efficiently. Similarly, in electronics manufacturing, these belts provide stable transport for sensitive components, preventing damage and ensuring quality control. Across all these industries, the ability to integrate plastic chain belts with automated sorting systems has proven to enhance productivity, reduce operational costs, and improve overall system reliability.

Challenges and Considerations

While plastic chain belts offer numerous advantages, there are several considerations for facilities looking to implement them. Initial investment costs can be higher than traditional conveyor belts, particularly for large-scale installations. However, these costs are often offset by lower maintenance requirements, reduced downtime, and longer service life.

Proper system design is also critical. The selection of the right type of plastic chain belt—whether smooth, textured, or perforated—depends on the specific application and product characteristics. Inadequate design or improper installation can lead to premature wear, misalignment, or inefficiencies in sorting operations.

Additionally, while plastic chain belts are highly durable, extreme conditions such as abrasive materials or extremely high temperatures may require specialized polymers or additional protective measures. Regular monitoring, preventive maintenance, and proper cleaning protocols are essential to maximize the performance and lifespan of these belts in automated sorting systems.

The Road Ahead

The future of automated sorting with plastic chain belts is bright, with continued advancements expected in materials science, robotics, and smart system integration. As industries increasingly rely on automation to meet growing consumer demand, plastic chain belts will remain a cornerstone of efficient and reliable material handling.

Emerging trends suggest that future systems will become more intelligent, self-optimizing, and energy-efficient. Conveyor networks will likely integrate real-time data analytics, predictive maintenance, and AI-driven sorting algorithms, further enhancing productivity and reducing operational risks. Plastic chain belts, with their modularity, durability, and adaptability, are uniquely positioned to support this evolution.

In addition to operational benefits, the sustainability aspect of plastic chain belts will gain prominence. Recyclable materials, reduced energy consumption, and minimal waste will become standard expectations in modern facilities. Manufacturers and operators that embrace these innovations will not only achieve higher efficiency but also align with global environmental goals, meeting both regulatory requirements and consumer expectations.

In conclusion, plastic chain belts are more than just a component of conveyor systems—they are a critical enabler of the next generation of automated sorting technology. Their combination of strength, flexibility, and adaptability ensures that industries can meet the demands of modern logistics, manufacturing, and distribution. As technology advances, the integration of plastic chain belts with smart systems and robotics will continue to redefine efficiency, accuracy, and sustainability in automated sorting, shaping the future of industrial automation for years to come.