10 Tips for a Successful China Pre-shipment Inspection

With China being a manufacturing powerhouse, many businesses around the world source products from this country. However, conducting pre-shipment inspections is crucial to ensure the quality and compliance of the goods before they are shipped to your destination. Pre-shipment inspections (PSIs) help mitigate risks, prevent costly mistakes, and maintain a level of control over your supply chain. In this article, we will provide ten essential tips for a successful

China pre-shipment inspection.

1. Choose the Right Inspection Company

Selecting a reputable and experienced inspection company is the foundation of a successful pre-shipment inspection. Look for firms with a proven track record, good references, and the necessary industry expertise. They should have a deep understanding of your industry, the products you’re sourcing, and relevant Chinese regulations.

2. Plan Ahead and Schedule Inspections in Advance

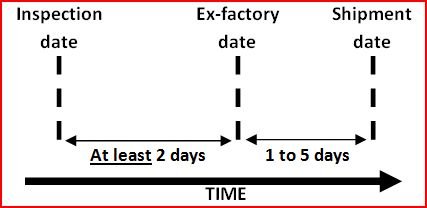

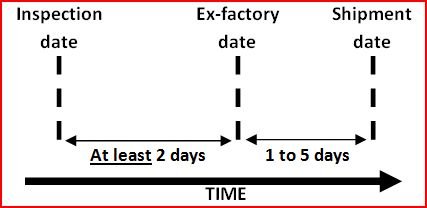

To avoid delays and ensure a smooth process, plan the pre-shipment inspection well in advance. Notify the inspection company as soon as you have an estimated production completion date. This allows them to allocate resources and schedule the inspection promptly.

3. Define Clear Inspection Criteria

Before the inspection, communicate your quality standards and specific inspection criteria to the inspection company. This should include product specifications, packaging requirements, labeling guidelines, and any applicable industry or regulatory standards. Providing detailed instructions ensures that the inspection focuses on the most critical aspects of the products.

4. Random Sampling and Inspection

Insist on a random sampling approach to ensure a fair representation of your order. Random sampling helps identify potential issues that might occur in the entire production batch. It prevents biased selections and increases the accuracy of the inspection results.

5. Be Present or Hire a Local Representative

Whenever possible, be present during the inspection or appoint a reliable local representative to attend on your behalf. Having someone on-site will enable real-time communication with the inspection team and quick resolution of any emerging concerns. Local representatives can also bridge the language and cultural gap, ensuring effective communication with the factory workers and the inspection team.

6. Check Documentation and Certifications

Verify that all required documentation, such as product certifications, compliance reports, and quality control records, are readily available for inspection. Ensure that the products meet the regulatory requirements of your country or any other destination market.

7. Review Production Process and Facilities

The pre-shipment inspection is not only about the final product but also an opportunity to assess the production process and facilities. Ensure that the factory follows ethical manufacturing practices, maintains a clean and safe environment, and complies with labor laws.

8. Address Non-Conformities Professionally

If the inspection identifies any non-conformities, work closely with the supplier to address them professionally. Prioritize critical issues that could affect the product’s quality or safety. Open communication and cooperation with the supplier are essential to resolving any problems and achieving the desired quality standards.

9. Establish a Continuous Improvement Process

Use the insights gained from pre-shipment inspections to improve your sourcing process continually. If recurring issues arise during inspections, work with the supplier to implement corrective actions and prevent similar problems in the future.

10. Maintain a Long-Term Relationship with Suppliers

Developing a strong, long-term relationship with your suppliers fosters trust and collaboration. Regularly conducting pre-shipment inspections can help maintain consistency in product quality and motivate the supplier to adhere to your standards.

Conclusion

Conducting pre-shipment inspections in China is an essential step to ensure product quality, compliance, and customer satisfaction. By partnering with a reputable inspection company, communicating clear criteria, and maintaining open communication with your suppliers, you can significantly increase the likelihood of successful inspections. Regular inspections and a commitment to continuous improvement will strengthen your supply chain and contribute to the success of your business in the global market.